I haven't been able to spend a lot on the router lately partially because I have had parts on order and I've just had so many other things going on.

I spent some time today back tracking a little bit. I had dumped a full linear bearing worth of balls on the floor by inadvertantly pulling the rail out and lost a few.. these needed to be replaced which meant taking the Z axis all apart. Other issues abound.

Here are pics from today. I had to leave because it was so hot and I am still waiting (six months) for windows and hence AC. I have two free days left in the week and plan on being done with the Z and finish machining parts for the X axis as well.

Birth of a machine

Tuesday, July 19, 2011

Saturday, July 16, 2011

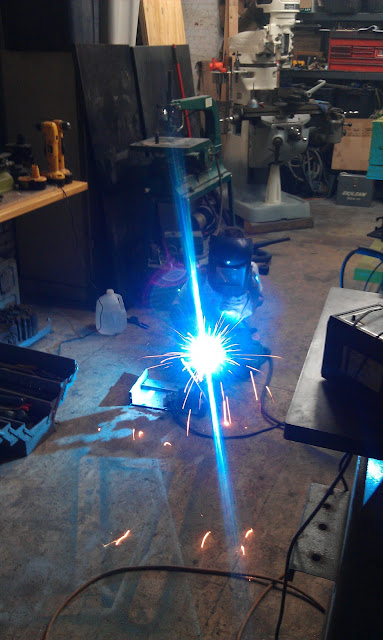

A new Welder in the Family

My son decided he had to learn how to weld this morning. So I gave him a few pointers, a mask and gloves and let him go to it.

Here are a few pics.

Here are a few pics.

Friday, July 15, 2011

Milling Machine is up and running!

I thought I had the mill together and working and found that the knee would rock a little when taking heavy cuts. The knee lock also wasn't working so well and I had broken motor mounts. I took the time to look up repairs online and progressively fixed them. Most of the repairs were made using parts fabricated or modified on mill or lathe.

Another shot of the mill in use. I haven't used a boring head in a while and managed to only burn out one bar. This is the router mount in progress.

Sunday, July 3, 2011

Follow up to new milling machine

Here are some follow on pics.

I've slowly been cleaning it up and painting it. I still have some work around the base and detailing. I only primed and epoxied it.. we'll see how long it lasts. A close up of the head after paint is below, It ended up being easier to just remove some parts after the fact and clean them rather than removing them and taping the holes. I chose off white because that is the color I had seen in R&D shops as a kid.

I've slowly been cleaning it up and painting it. I still have some work around the base and detailing. I only primed and epoxied it.. we'll see how long it lasts. A close up of the head after paint is below, It ended up being easier to just remove some parts after the fact and clean them rather than removing them and taping the holes. I chose off white because that is the color I had seen in R&D shops as a kid.

Friday, June 17, 2011

New (to me) Milling machine

I rigged this out of an upper floor yesterday. I was able to clean it up in a few hours, adjust the gibs and get it close to where I want it with a pallet jack. I'll drop it to the floor, bolt and wire it next week.

I can't tell you how cool it feels to own a Bridgeport.. I have wanted one my whole life so to be able to get one at no cost and learn the in's and out's of it by having to take it apart was just amazing! I am looking for collets, fly cutters, chucks etc. today and hope to have it up and running soon. It'll sure beat a grinder and little drill press.

Pic of Mill being disassembled and rigged out.

I can't tell you how cool it feels to own a Bridgeport.. I have wanted one my whole life so to be able to get one at no cost and learn the in's and out's of it by having to take it apart was just amazing! I am looking for collets, fly cutters, chucks etc. today and hope to have it up and running soon. It'll sure beat a grinder and little drill press.

Pic of Mill partially reassembled and cleaning underway.

Friday, June 10, 2011

Hoverbike Concept

hoverbike prototype

'hoverbike' prototype, invented by australian mechanical engineer chris malloy

working in his spare time, australian mechanical engineer chris malloy claims to have invented a working 'hoverbike',

operated like a motorcycle. measuring 9.8 long by 4.3 wide and 1.8 feet high (3 x 1.3 x 0.55m) the prototype bike

seats a single pilot between two oak and carbon fibre-blade two-blade propellers, currently exposed but which

for safety reasons will be covered in mesh in future models. in basic flight design, the bike is modeled after

tandem-rotor chinook helicopters, whereby the two rotors rotate in opposite directions, canceling one another's torque

and thus increasing stability and efficiency of the vehicle.

the 'hoverbike' is controlled completely by handlebars, via actions similar to those used for motorcycles. forward and reverse

movement is accomplished through two grips, one of which increases the thrust while the other adjusts the angle of the control vanes

positioned below the rotors, pitching the nose of the vehicle down for forward movement and up for backwards.

front view during tethered testing

malloy estimates that the 'hoverbike', whose 4-stroke engine drives 80kW of power to the propellers, generating 7500rpm,

is capable of reaching heights of over 10,000 feet and of traveling 150 knots (173mph, or 278km/h). the vehicle's 30L primary tank

can be supplemented with additional fuel storage but even on its own should offer a range of 92 miles (148km) when traveling

at 80 knots (92mph or 148km/h).

although the relatively low number of parts makes the craft simpler and more reliable than most helicopters,

safety concerns for the bike have led malloy to make most engine and operating features triply redundant.

two explosive parachutes can be attached to the vehicle's frame, although malloy recommends that the pilot

simply wear an emergency parachute so that he has the option of dislodging from the vehicle if necessary.

full profile view

3/4 top view

aerial view, placed next to a car for size reference

with tests already conducted of the prototype tethered to the ground, the first flight tests are planned for the coming months.

the 'hoverbike' is classified in the united states as an 'ultralite' vehicle, meaning that it would not require a pilot's license

to be operated. malloy hopes to begin limited production of the bike within a year, estimating the cost at about 40,000 USD

for a run of 100 units per year, and on par with performance motorcycles if demand rises to about 1000 units per year.

'hoverbike' prototype, invented by australian mechanical engineer chris malloy

working in his spare time, australian mechanical engineer chris malloy claims to have invented a working 'hoverbike',

operated like a motorcycle. measuring 9.8 long by 4.3 wide and 1.8 feet high (3 x 1.3 x 0.55m) the prototype bike

seats a single pilot between two oak and carbon fibre-blade two-blade propellers, currently exposed but which

for safety reasons will be covered in mesh in future models. in basic flight design, the bike is modeled after

tandem-rotor chinook helicopters, whereby the two rotors rotate in opposite directions, canceling one another's torque

and thus increasing stability and efficiency of the vehicle.

the 'hoverbike' is controlled completely by handlebars, via actions similar to those used for motorcycles. forward and reverse

movement is accomplished through two grips, one of which increases the thrust while the other adjusts the angle of the control vanes

positioned below the rotors, pitching the nose of the vehicle down for forward movement and up for backwards.

front view during tethered testing

malloy estimates that the 'hoverbike', whose 4-stroke engine drives 80kW of power to the propellers, generating 7500rpm,

is capable of reaching heights of over 10,000 feet and of traveling 150 knots (173mph, or 278km/h). the vehicle's 30L primary tank

can be supplemented with additional fuel storage but even on its own should offer a range of 92 miles (148km) when traveling

at 80 knots (92mph or 148km/h).

although the relatively low number of parts makes the craft simpler and more reliable than most helicopters,

safety concerns for the bike have led malloy to make most engine and operating features triply redundant.

two explosive parachutes can be attached to the vehicle's frame, although malloy recommends that the pilot

simply wear an emergency parachute so that he has the option of dislodging from the vehicle if necessary.

full profile view

3/4 top view

aerial view, placed next to a car for size reference

with tests already conducted of the prototype tethered to the ground, the first flight tests are planned for the coming months.

the 'hoverbike' is classified in the united states as an 'ultralite' vehicle, meaning that it would not require a pilot's license

to be operated. malloy hopes to begin limited production of the bike within a year, estimating the cost at about 40,000 USD

for a run of 100 units per year, and on par with performance motorcycles if demand rises to about 1000 units per year.

Wednesday, June 8, 2011

Autodesk Photofly results

I recently discovered Autodesk Photofly and gave it a try. below are the results. It took a couple of attempts but is relatively easy to use even for a novice. I am going to play with some of the dimensional qualities of these models and then attempt to rout in 3D.. this is very exciting and replaces thousands of dollars worth of equipment if even close to being dimensionally accurate.

Subscribe to:

Comments (Atom)